From urban to semi-rural areas, from the installation of single compressor units to whole refrigeration plant projects, we can provide you with the following Value Added Services.

Equipment and Component Sales

Consulting / Engineering Services

After Sales Services

Local Fabrication / Assembly

Installation and Commissioning

Operation and/or Maintenance Services

We have also partnered with leading businesses in the Refrigeration Industry to help provide and distribute the proper equipment for your facilities. They are listed in the product sections below:

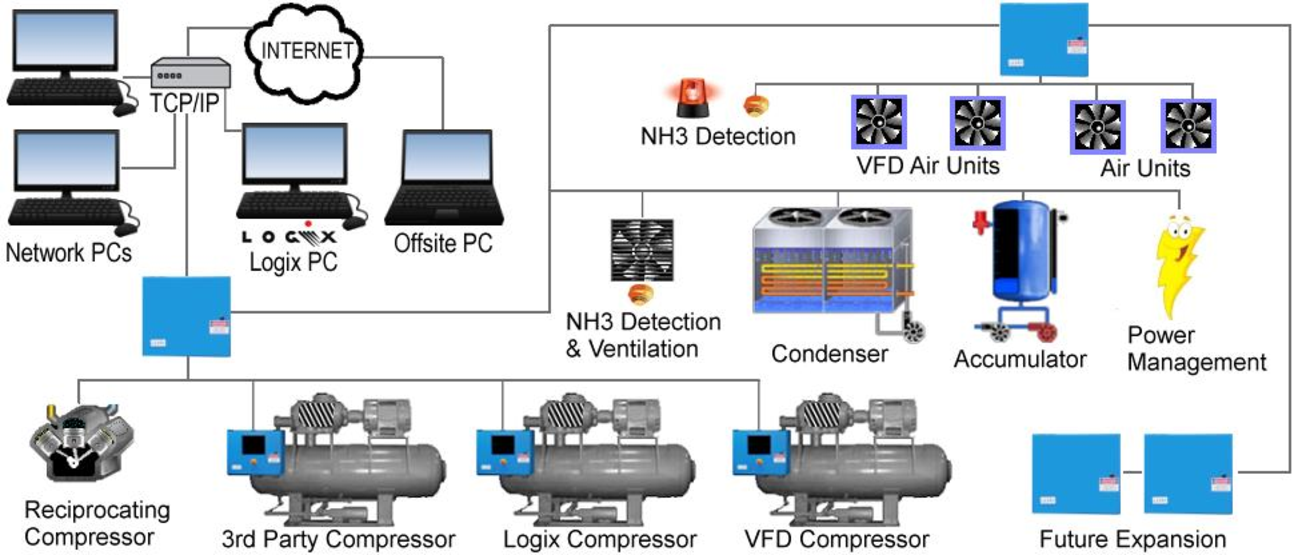

LogixⓇ raises the bar continually with leading-edge computerized controls designed to lower energy costs, improve facility operations and boost your bottom line. It's the top refrigeration energy management systems manufacturer serving the food/beverage and cold storage industries with digital monitoring systems and outstanding service — as Logix says, "your success is our focus".

Logix Systems leverage two industry-leading components for the best energy management systems in the business:

Logix customers seek the energy efficiencies and cost savings our control solutions deliver. Refrigeration systems use huge amounts of electricity and typically consume 65-85% of a cold storage facility's total energy usage. Clearly, the high cost of inefficient facilities is unacceptable to companies wishing to succeed in today's increasingly competitive environment.

Fortunately, Logix has battle-proven solutions for companies now facing the double burdens of rising energy costs and emerging environmental mandates. Since its founding in 1990, our company has been delivering advanced refrigeration controls and management software that routinely reduce energy demands by 20-40%. To achieve these outcomes, our solutions deliver two fundamental types of benefits:

Howden Compressors is a specialist screw compressor manufacturer based in Glasgow. They design and manufacture both oil injected and oil free screw compressor units building on the experience gained since the company first commercialized screw compressor technology from the 1930s.

The units are used in a wide variety of refrigeration applications, and form the heart of gas compression systems required for demanding applications in the oil/gas and petroleum industries.

Howden process compressors and complete compressor packages are used in the petroleum, petrochemical, refrigeration, fuel gas and other markets where performance and reliability are crucial. The company has over one hundred years of experience behind them and supplies their compressors to API or equivalent industry standards.

With over 50 years of experience, SES International is a specialist in compressor packages for the refrigeration, petrochemical and oil and gas industries. They supply high quality, tailor-made compressor packages backed-up by reliable service. With a proven track record, SES has the right technologies to achieve customers' business goals. Delivering the most cost-effective and efficient design for your compressor package: from basic “stand-alone” unit to full turnkey compressor stations with all its necessary secondary equipment as scrubbers, heat exchangers and control units comprising all customers specifications. Working closely with their customers, SES provides EPC and project management resources to execute safe, reliable compressor packages that are easy to operate and maintain.

All within the defined project schedules and budgets.

WINTER, as a specialist in ammonia (NH3) refrigeration systems, has a wide range of various refrigeration system solutions within its product portfolio. Their strength is the custom-made design of their packages and products, considering the leading international standards API, ASME, GOST, TEMA, etc., which assure that the company's clients receive the highest standard for their demands. Ammonia (R717), with its zero ODP and zero GWP, is currently the best choice when clients are looking for a highly efficient, reliable, and sustainable solution for an industrial refrigeration system. Besides ammonia and other natural refrigerants such as CO2 (R744), Propane (R290), Propylene (R1270), and Iso-Butane (R600a). WINTER can also provide a complete range of products and packages for the industrial refrigeration industry with all other common refrigerants (HFCs) upon customer request as well.

HASEGAWA reciprocating compressors have achieved worldwide recognition for their Quality, Reliability, and Efficiency. Hasegawa is dedicated to the promotion of its Total Engineering and Operation program to receptive markets worldwide. By creating an intensive team to research and develop the technological trends and requirements of the refrigeration industry, Hasegawa has committed itself to the future well-being of our environment, our natural resources and society as a whole. It is under the motto of "Internationalization, Foresight, and Innovation" that Hasegawa bases its success well into the future.

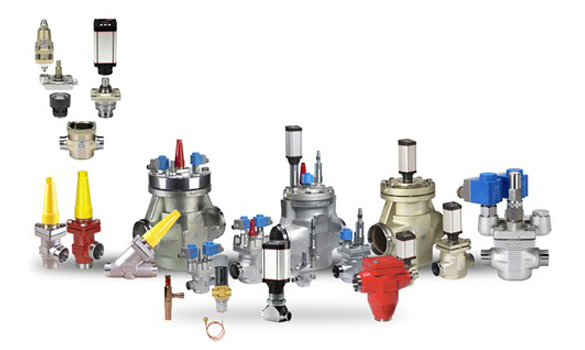

Climate change regulations, new demands for energy efficiency, higher comfort level expectations, cold chain reliability, and pressure to reduce overall cost of ownership are driving the current developments and installations in a competitive marketplace. Through Danfoss, HVAC-R professionals including OEMs, installers, wholesalers, owners, and end users have access to the widest portfolio of user-friendly solutions available on the market. The company's solutions fit a broad variety of applications and enable temperature-controlled environments with near-zero downtime. Smart functions automatically warn of potential failures and ensure that routine service calls take place on time. Their innovative and popular technologies include TurbocorⓇ compressors, Scrolls with IDVs, Optyma condensing units, Micro Channel and Micro Plate Heat Exchangers, ETS ColibriⓇ Expansion Valves, TU/T2 valves, and EVR solenoid valves.

Hansen Technologies introduces the HS4D Two Step Solenoid Valve. The HS4D is based on the same strength, reliability, design principles and craftsmanship as the standard HS4A Solenoid Valve — with added versatility.

The Hansen HS4D is a reliable, flange-bodied valve which can be used anywhere a traditional refrigerant solenoid valve employed. The partially open position can help minimize liquid velocity shock (liquid hammer). When used as a liquid feed valve, partial opening of the HS4D can gradually introduce flow before switching to the fully open position. Additionally, the two step solenoid valve can be used to gradually slow liquid flow prior to fully closing the valve to minimize hydraulic shock.

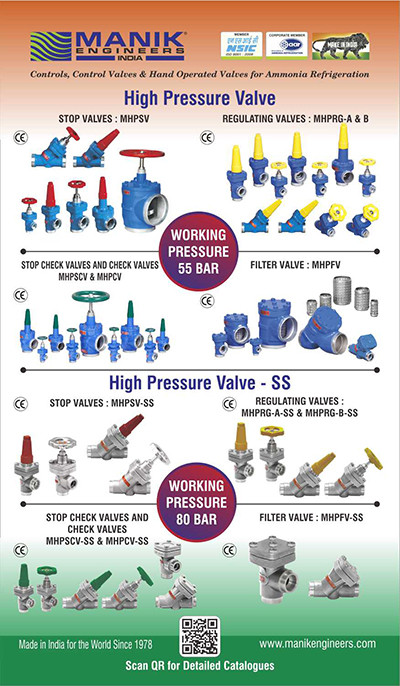

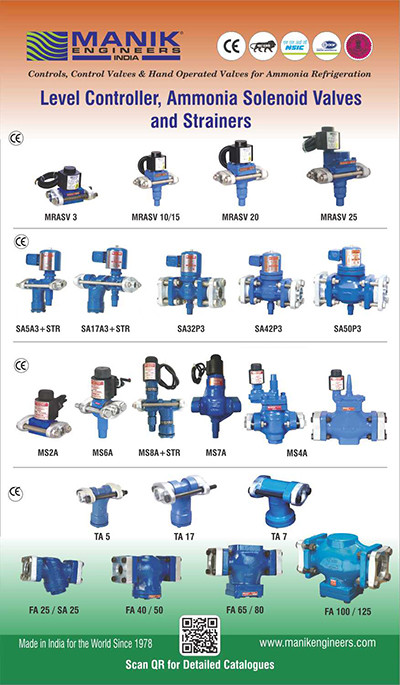

Manik Engineers manufactures controls, control valves for automation of refrigeration plants since 1978, and is truly following the dream of Honorable Prime-Minister Narendra Modi, Made in India. The company was “Made in India” since 1978. Their products include Ammonia solenoid valves, Liquid level controllers, Pressure / Temperature Regulating Valves, Stop Valves, In Line Check (Non Return) Valves, Safety Valves, Hot Gas Defrosting system for gravity and pump recirculation plants, Screw & Piston Compressor Capacity Controllers, sensors, transmitters, indicators and controllers fortemperature, pressure, relative humidity, carbon dioxide & ethylene.

With nearly a century of technological and engineering excellence in refrigeration, our air coolers are second to none. High quality, robust and reliable products — give your business the very best.

A wide range of Güntner air cooled products come with an HACCP certification too, to meet your country's hygiene requirements.

What's more, all of the COMPACT coolers come with a 3-year warranty as standard, giving you even more peace of mind.

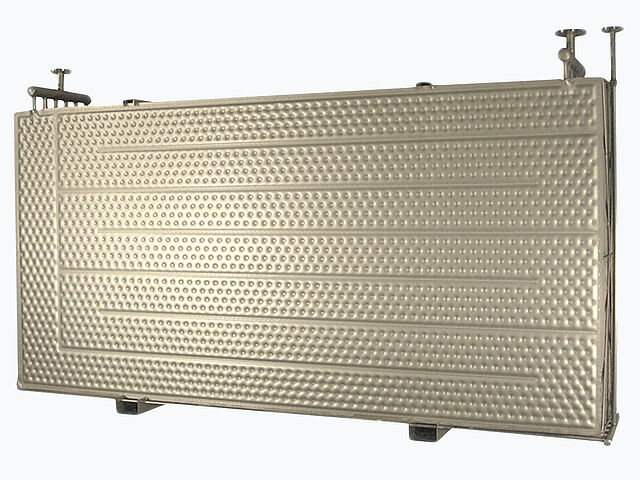

In view of the specific needs and expectations of customers in the field of heat transfer in the case of direct product cool down, provide the calculations on one hand and the manufactured technical systems and components on the other hand. Consequently, both are tailored to functionality and efficiency, but also never to loose sight of process stability of the respective field of application. Heat Transfer Technology AG's ice water systems, falling film chillers, ice banks or heat exchange systems have this stability to ensure that the direct product cooling process chain is not interrupted.

Thermofin will always offer you the right exchanger: the one for sustainable exchanges...

To achieve this goal, Thermofin shall offer its clientele:

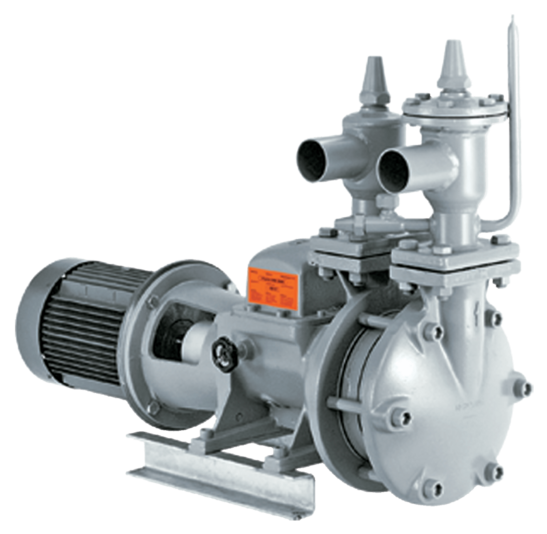

Refrigeration canned motor pump with the characteristics of advanced design, compact structure, high efficiency, energy saving, low noise, no leakage, safely and reliability, etc.

This series canned motor pump for refrigerating are specially-designed for the refrigerating which is particularly suitable for delivering cryogens such as: ammonia, freon, CO2, etc.

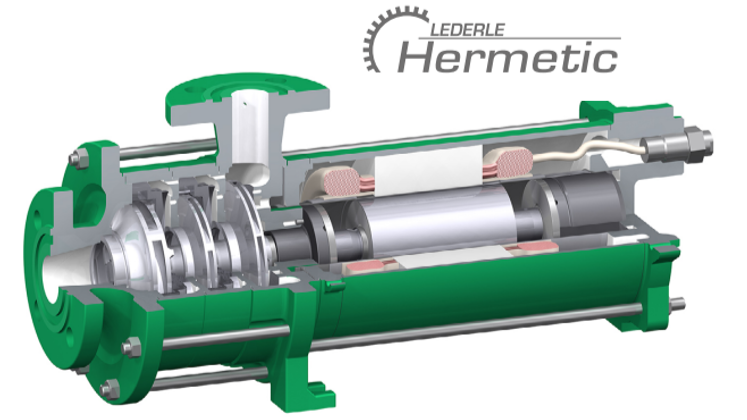

HERMETIC pumps have been successfully used for reliable cooling of plants and production processes. HERMETIC has been dedicated to the development and hermetically sealed pumps for a period of 50 years. HERMETIC pumps are designed for applications in the chemical and petrochemical industry, as well as for process technologies. The refrigeration industry also benefits from this experience made in these industries. There are more than 78,000 HERMETIC pumps installed in refrigeration plants worldwide.

Our product for the industrial refrigeration industry are solely produced in Aachen, Germany. Being located geooraphically at the heart of Europe, where three countries, the Netherlands, Belgium and Germany meet, the company is strongly export-oriented. Their products are manufactured in modern production facilities and they have received accreditation to DIN ISO 9001 and pressure vessel directice. The company's extensive parts stock provides fast and reliable spare part availability.

Stainless steel and energy-efficient cooling technology make the ECOSS G3 evaporative condenser more durable and less resource-intensive than traditional galvanized-steel cooling towers. This helps reduce the environmental impact and operational costs of industrial refrigeration and process cooling in food and beverage production, logistics and other industries to a minimum.

The SWL evaporative condenser is a piece of high-efficiency heat exchange equipment which comes into being on the basis of adopting the internationally-advanced heat-exchange technology. The evaporative condenser uses water and air as the cooling medium.

Humanized design structure with large access door and sufficient inner room, enables maintainers to conveniently conduct inspection and repair work inside the SWL evaporative condenser. In addition, ball cock and dust-gauze can be examined and repaired under online maintenance. Moreover, the same direction of airflow and water flow makes it very convenient to examine and repair nozzles and coils when the machine is running.

EVAPCO is dedicated to designing and manufacturing the highest quality products for the evaporative cooling and industrial refrigeration markets around the globe. EVAPCO supports its worldwide customers with manufacturing facilities and sales offices strategically located around the world.

According to demand of market, Meluck designed this new series XJB-E on the basis of the XJB series. This new series of products feature a box-type structure with a hermetic compressor and control box, which is compact and pleasant-looking, applicable to cold display cases, cold storage rooms, ice producers, etc. The applicable temperature ranges are:-5°C to -15°C,-5°C to -5°C and -15°C- to -25°C. They can be widely used in hotels, restaurants, hospitals, agricultural & chemical industries, and all other places where cold storage is needed.

Zanotti S.p.A. has a great experience and it is a synonym of undiscussed quality, reliability and safety in manufacturing refrigerating equipment for the food industry.

The main business of the company consists of the most appropriate use of "cold" for refrigeration and storage of agro-foodstuffs, drying and seasoning of cold cuts and cheese, grain chilling in silos and truck refrigeration.